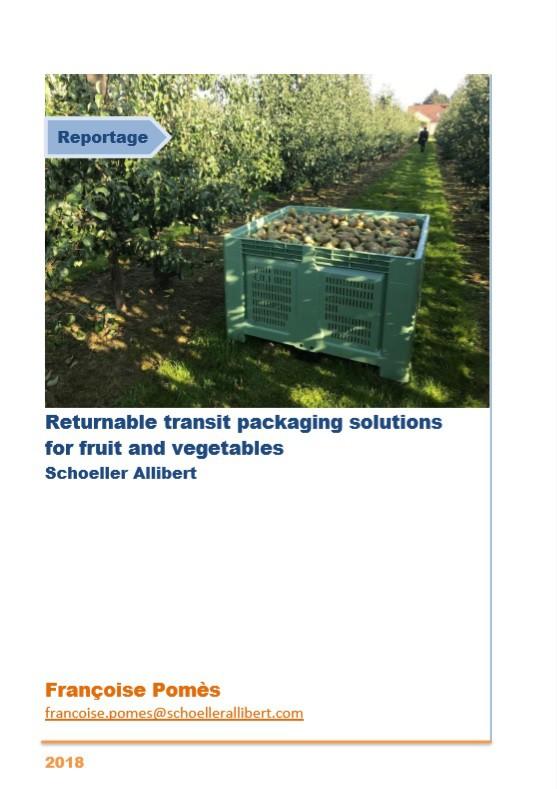

Returnable transit packaging solutions for fruit and vegetables

Author

Pomès, Françoise

10 pages

By Françoise Pomès. 2018. 10 pages.

Schoeller Allibert has been developing solutions for the harvesting, storage, transport and processing of fruit and vegetables since 1970. Initially the company offered 500x300 footprint harvesting and storage crates to match the size of the wooden boxes which were in use at the time.

The main advantages of plastic boxes appeared to be obvious; the plastic crates were lighter, did not promote mold, were resistant to moisture, had a constant tare weight whatever the climate and environment conditions and were extremely long lasting. In the cold storage chambers they could be easily stacked and pallets on top of each other optimized space use.

Initially, Schoeller Allibert offered crates for apples and tomatoes, and later developed fragile stone fruit models featuring a special wave shaped base so that the fruit would gently settle, reducing bruises and surface damage when transported from orchards to cold storage chambers and on to packing or processing sites.

Françoise Pomès. Dir. of Global Marketing Schoeller Allibert. 2018. Large format pallet boxes and smaller crates feature innovations are for the transport of green leafy salads. 10 pages